Introduction

The complete gold washing plant mainly uses gravity separation technology to mine placer gold ore. The main equipment includes gold washing machine, centrifugal concentrator, shaking table, spiral chute, etc. Our gold washing plant can process 300 tons of placer gold ore per hour.

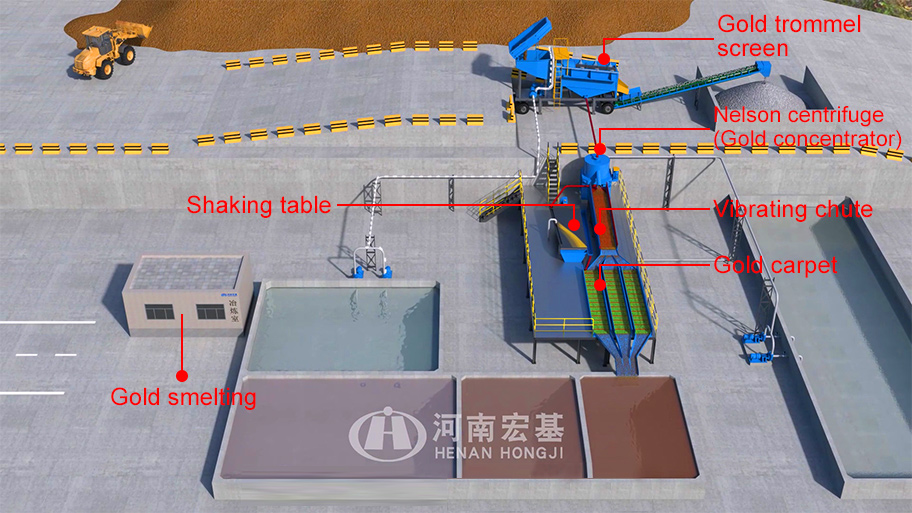

Process of Gold Washing Plant

The raw ore is fed into the mobile gold washing machine for ore washing and sorting.The materials larger than 5mm are transported to the waste rock area and the materials smaller than 5mm are separated by the Nelson centrifuge.the centrifugal concentrate enters the shaking table for selection and the centrifugal tailings enter the agitation chute for re-selection.The tailings of the agitation chute enter the fixed chute and the tailings of the fixed chute enter the tailings sedimentation tank for sedimentation. The upper layer water in the tailings tank afer sedimentation is recycled.The concentrates of the agitation chute and the fixed chute are collected regularly and sent to the shaking table.The tailings of the shaking table flow to the fixed chute.The concentrate is send to the smelting system via a trolley.The collected concentrate is mixed with mercury,evaporated,and smelted to finally obtain pure gold.

Key equipments in a gold washing plant

① Gold Washing Machine

Gold washing machine is a device specially designed to separate gold from ore, gravel or soil by washing and sorting to achieve efficient separation of gold from other impurities. Its core goal is to increase the recovery rate of gold and reduce the labor intensity of manual panning.

② Shaking Table

The shaking table is also known as a gold shaking table, gold separation table, or concentrating table. It is a fine gold recovery equipment common in the gold shaker wash plant, alluvial gold mining plant to separate concentrates, medium concentrates, and tailings according to material density and grain size. Shaking table can not only be used as an independent beneficiation machine, but it often works with jig separator machines, centrifugal concentrators, sluice boxes, flotation equipment, magnetic.

③ Centrifugal Concentrator

Centrifugal concentrator is a kind of gravity beneficiation equipment, which generates great centrifugal force when rotating at high speed, strengthens the gravity separation process, and makes fine ore particles more effectively recovered. Experiments show that it is particularly effective for the separation of single gold in vain gold ore. It can also be widely used to recover single gold in other metals.

The benefits of choosing us

We are a famous mining equipments producer , we make the following commitments to you.

- 1.We are a manufacturer , not an intermediate trader, and we can offer you competitive prices.

- 2.We have a strong processing capacity to ensure that all machines are delivered on time.

- 3.We have more than 60 engineers who can quickly provide you with solutions and quotations

- 4.We provide you with installation and other after-sales services to ensure the stable operation of your production line.

- 5.We have dozens of project cases in Africa, Asia, America , etc. So many successful cases are the best testimony of our strength and reputation

FAQs

-

1. How can I get a quote?

You can contact us via WhatsApp, email, online consultation, etc. Our engineers will contact you within 2 hours. However, you need to provide information about the gold ore, such as grade, pictures, and of course the capacity, so that the quotation we provide you will be more accurate.

-

2. Is the provided solution free of charge?

The solution we provide you is not only free, but also professional. We have 20 years of experience in mineral processing technology design.

-

3. Do you provide installation services?

After the equipment arrives, we will send engineers to your site with installation drawings to guide the local construction team to install it. You can rest assured that we will always serve you until your gold processing plant can run normally.

+8619138015336

+8619138015336