Which copper processing plant is right for me ?

Copper ore is divided into sulfide ore (oxidation rate is less than 10%), oxidized ore (oxidation rate is greater than 30%) and mixed ore according to the different oxidation rate. Sulfide ore, easily selected mixed copper ore is treated by flotation method,For difficult mixed copper ore and difficult copper oxide ore, hydrometallurgy or hydrometallurgy combined with flotation are more used to treat.

-

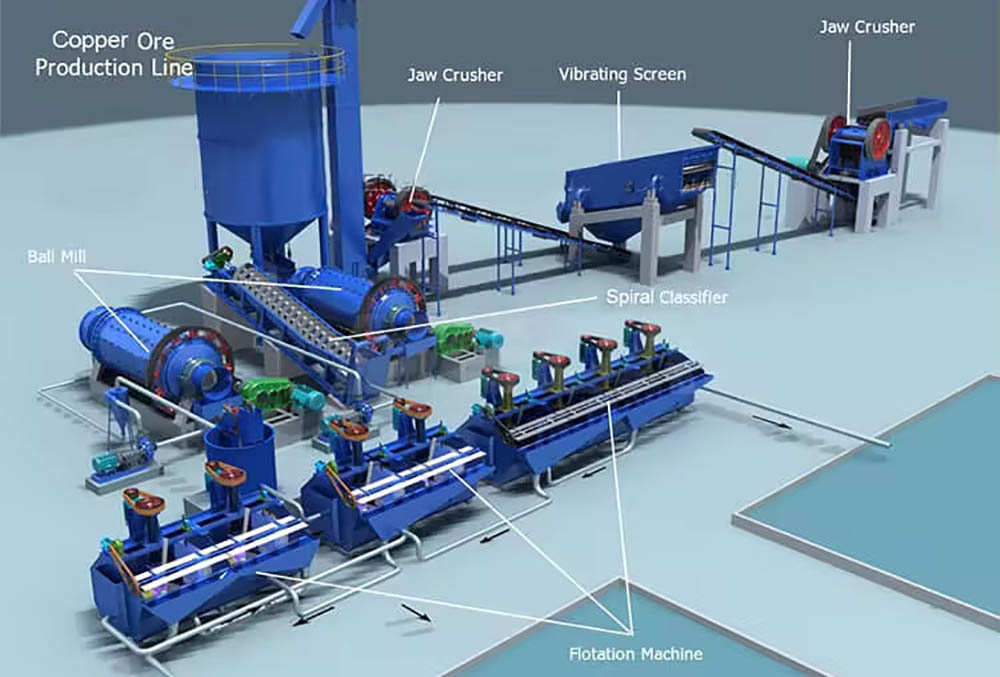

Copper Flotation Plant

Copper flotation plant adopts flotation process for copper separation. Flotation is one of the most commonly used processes in copper beneficiation. In the flotation process, copper ore and other impurity minerals are flotation to different degrees by adding various chemicals to the pulp, so as to realize the separation of copper ore and impurity.

Feturers :High separation efficiency, and it is suitable for the treatment of low grade

-

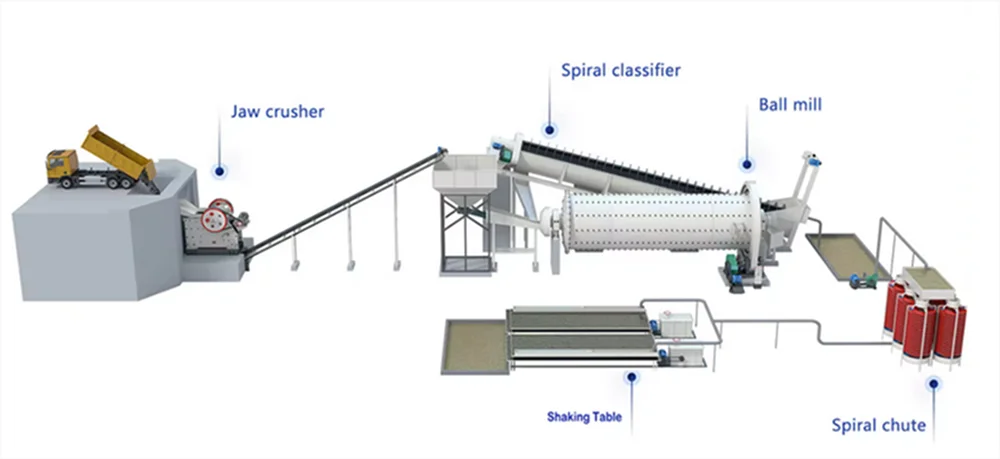

Copper Gravity Plant

Gravity separation is a mineral processing operation that takes advantage of the different settling rates of ore particles in heavy media. In the process of gravity separation, by adding heavy media to the pulp, such as heavy liquid or heavy pulp, the copper bearing ore and the impurity ore produce different settling speed, so as to achieve their separation. Gravity separation process is usually used to treat copper ore with fine particle size

Feturers :it is usually used to treat copper ore with fine particle size.

Two copper processing plants with different yields

We share with you two different copper procesing plants, they may not meet your requirements, but you can contact us for unique solutions and quotes.

(1) 2000T/H copper processing plant

The ore is primary ore. According to the mineral combination, structure and structural characteristics, the natural types of ore are roughly divided into brass, pyrite, magnetite tremolite skarn. According to the main useful elements in the ore are copper, iron, etc., the ore industry type is copper iron ore

| Raw Material | Delafossite |

| Grade | 5.61g/t |

| Feedback | The mineral yield of copper is 6.40%, sulfur is 5.90% and iron is 54.36% |

| Cost | 890000 or less |

(2) 500T/D copper processing plant

The mineral composition of the project is relatively simple, and the metal minerals are chalcopyrite, pyrite and so on. Non-metallic minerals are mainly quartz, chlorite and so on. From the results of multi-element analysis, it can be seen that the element that can be recycled in the ore is copper. The grade of copper in the raw ore is 0.80%.

| Raw Material | Chalcopyrite,pyrite |

| Grade | 0.8% |

| Feedback | Concentrate with yield of 3.45%, copper grade of 20.78% and copper recovery of 90.05% |

| Cost | Contact us to get the quote |

The benefits of choosing us

We are a famous mining equipments producer , we make the following commitments to you.

- 1.We are a manufacturer , not an intermediate trader, and we can offer you competitive prices.

- 2.We have a strong processing capacity to ensure that all machines are delivered on time.

- 3.We have more than 60 engineers who can quickly provide you with solutions and quotations

- 4.We provide you with installation and other after-sales services to ensure the stable operation of your production line.

- 5.We have dozens of project cases in Africa, Asia, America , etc. So many successful cases are the best testimony of our strength and reputation

FAQs

-

1. How can I get a quote?

You can contact us via WhatsApp, email, online consultation, etc. Our engineers will contact you within 2 hours. However, you need to provide information about the gold ore, such as grade, pictures, and of course the capacity, so that the quotation we provide you will be more accurate.

-

2. Is the provided solution free of charge?

The solution we provide you is not only free, but also professional. We have 20 years of experience in mineral processing technology design.

-

3. Do you provide installation services?

After the equipment arrives, we will send engineers to your site with installation drawings to guide the local construction team to install it. You can rest assured that we will always serve you until your gold processing plant can run normally.

+8619138015336

+8619138015336