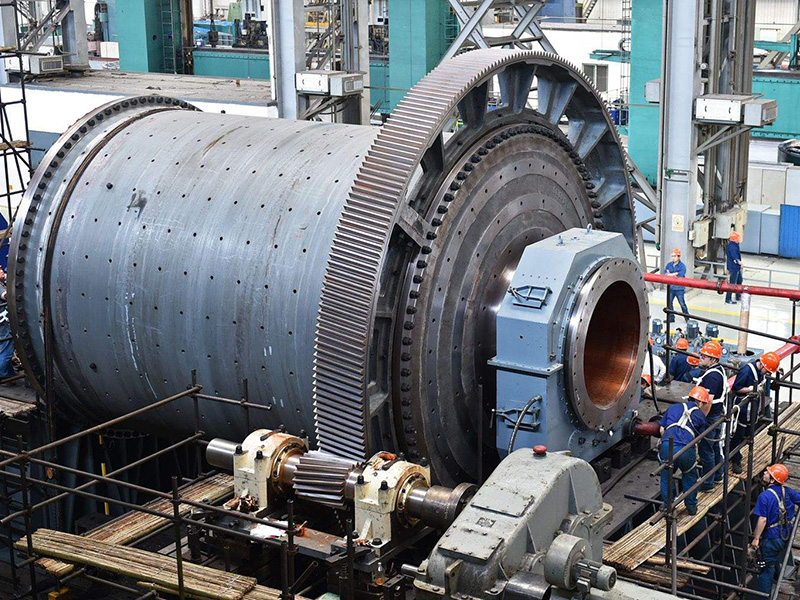

Desciption

Ceramic ball mill has the characteristics of less investment, energy saving and electricity saving compared with similar products, novel structure, easy operation, safe use, stable and reliable performance, etc. It is suitable for mixing and grinding of ordinary and special materials. The user can choose the appropriate model, lining plate, and medium type according to the specific gravity and hardness of the material, and the production capacity and other factors. The lining plate can be made of ceramic, silica, rubber, and metal.

Features

- 1.Stable and reliable performance.

- 2.It can improve the grinding precision and improve the quality of finished products.

- 3.The batch mill is more energy-saving and can save 40%-50% of electricity consumption than traditional ball grinding mill.

Parameter

| Model | Capacity (tons/time) |

Cylinder Speed (r/min) |

Motor Power (kw) |

Weight (t) |

|---|---|---|---|---|

| TCQ910×1120 | 0.2 | 36 | 5.5-11 | 2.6 |

| TCQ1200×1400 | 0.5 | 32 | 11-18.5 | 4.3 |

| TCQ1500×1800 | 1 | 28 | 15-22 | 7.5 |

| TCQ1800×2100 | 1.5 | 26 | 18.5-30 | 10.5 |

| TCQ2100x2100 | 2.5 | 22 | 22-37 | 14 |

| TCQ2200×2400 | 3 | 20 | 28-45 | 18 |

| TCQ2500×2900 | 5 | 16 | 37-55 | 26 |

| TCQ2800×3700 | 8 | 14.5 | 55-75 | 35 |

| TCQ3000×3700 | 10 | 14 | 75-90 | 46 |

| TCQ3200×4600 | 15 | 13.5 | 90-110 | 63 |

+8619138015336

+8619138015336