Introduction

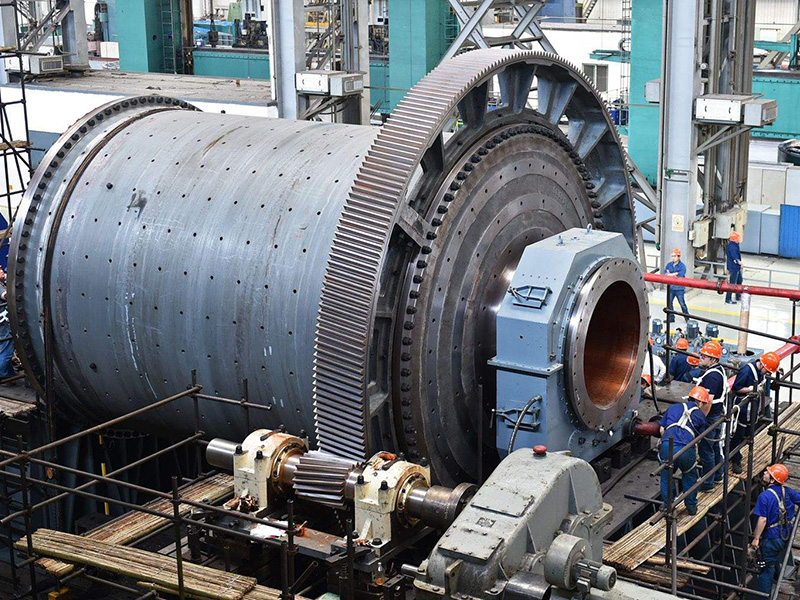

Silica sand beneficiation is the process of obtaining refined or high-purity quartz sand by removing a small amount of impurities from the silica sand. The main processes include analytical removal of impurities and silica sand purification.

Process of Silica sand Beneficiation

About Silica sand

Silica sand has high fire resistance, Silica sand is usually divided into ordinary Silica sand, refined Silica sand, high purity quartz sand, molten Silica sand sand and silica powder.

Because of its unique physical and chemical properties, quartz sand is commonly used in glass, ceramics, refractory materials, photovoltaic and other industries

Purification methods of Silica sand

Depending on the raw material composition and finished product requirements, we can provide you with the following silica sand purification processes

① Sand washing and mud removal

Washing method is a basic method of purification of silica sand, which is mainly used to remove sediment and impurities in silica sand. After being treated by the water washing method, the purity of the quartz sand can be increased to about 90% to 95%.

② Gravity method

Impurities in silica sand are mainly other minerals, metallic elements, inorganic salts, etc., and the density of these impurities is usually lower than that of quartz sand. Therefore, it can be separated from silica sand by gravity separation equipment, and the purity of silicon dioxide (SiO2) can be increased to more than 99%

③ Magnetic separation method

The magnetic separation method of silica sand can separate biotite, magnetite, hematite and other magnetic impurities in quartz sand. After repeated magnetic separation and tailings post-treatment, the impurity content in silica sand can be further reduced, and the purity of quartz sand can reach more than 98%.

④ Flotation method

Flotation separation of silica sand, mica and feldspar can make the purity of silica sand reach 99.3%-99.9%, after washing, desliming, magnetic separation, flotation basically meet the needs of industry.

⑤ Acid leaching method

Acid leaching makes use of the properties that silica dissolves in acid (except hydrofluoric acid) and other impurities minerals can be dissolved by acid to achieve further purification of silica sand. After acid leaching, high grade silica with purity of 99.99% can be obtained.

+8619138015336

+8619138015336