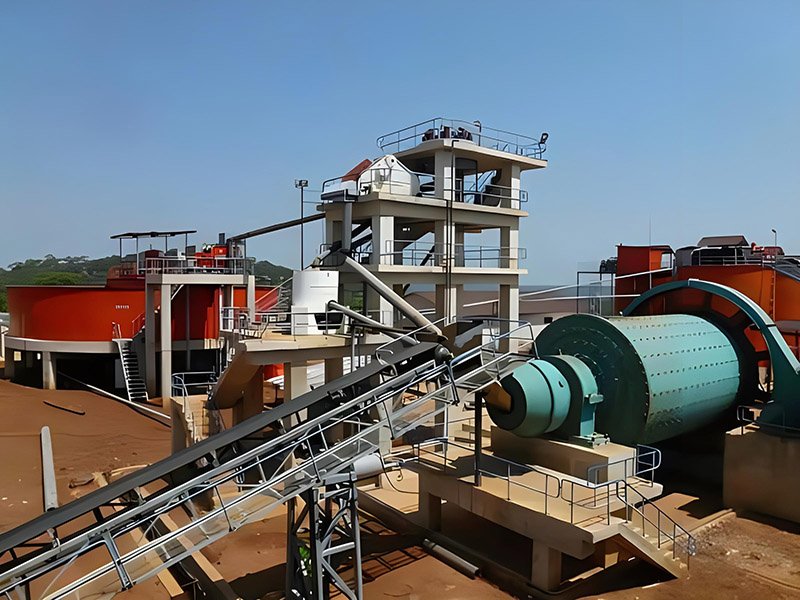

Introduction about Phosphate Beneficiation Process

According to the different properties of phosphate ore, phosphate ore beneficiation methods include flotation, scrubbing and desliming; Gravity separation, chemical leaching, combined beneficiation; Photoelectric sorting, magnetic cap method, etc. Flotation is the most used phosphate ore processing process, including direct flotation, reverse flotation, reverse flotation and double reverse flotation.

Process of Phosphate Beneficiation Process

Forward flotation processDirect flotation, which uses effective inhibitors to inhibit gangue minerals and accumulates phosphate minerals in foam with collector, can be applied to low-grade phosphate ores, including magmatic apatite and sedimentary metamorphic phosphate limestone ores.

Reverse flotation process

It is mainly used for the separation of phosphate rock and dolomite, and the dolomite is enriched in the tank with the fatty acid collector in the weak alkaline medium. The advantage is that the room temperature flotation is realized, and the coarser particle size of the products in the tank is conducive to the post-treatment of the products.

Double reverse flotation process

Double reverse flotation is under alkaline conditions, let the silicate surface with positive charge and use anionic collector to achieve the purpose of mineral separation, that is, first flotation dolomite, and then reverse flotation of silicate, the product in the tank is heavy concentrate, the production line can be carried out at room temperature, coarse-grained conditions.

+8619138015336

+8619138015336