Introduction

We mainly use magnetic separation method to select iron ore, which is also commonly used in the world. Strong magnetic iron minerals such as magnetite are separated by low intensity magnetic separation. The weakly magnetic minerals dominated by hematite were separated by high intensity magnetic separation.

Some magnesite and limonite also use high intensity magnetic separation equipment. Simple tail drop restore geological grade sales Simply improve grade and sales.

Process of Iron Beneficiation

About Iron Ore

Iron ore is a mineral aggregate containing iron elements or iron compounds that can be economically utilized. Any ore containing economically available iron is called iron ore.

There are many kinds of iron ores. The main 4 types of iron ores are Magnetite , Hematite, Limonite, and Siderite. According to the different properties of iron ores, their beneficiation methods are also different.

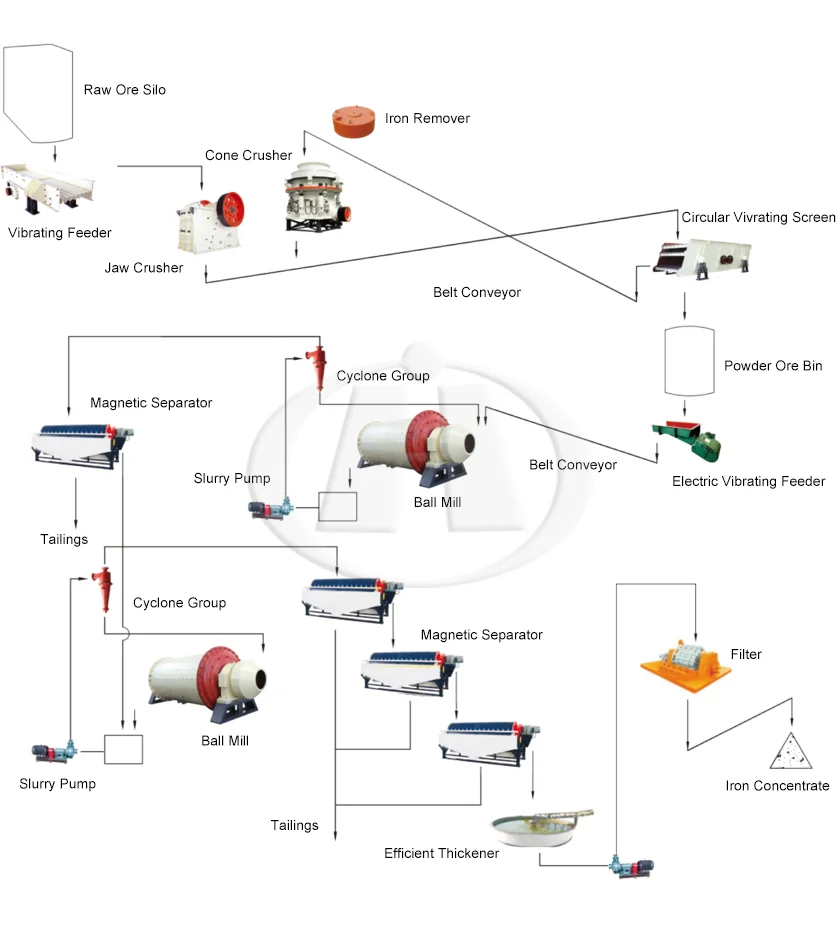

Process Flow:

The iron beneficiation process is mainly divided into the following 5 steps:

① Crushing and grinding

The mined iron ore is crushed and ground, and this process is mainly completed by jaw crusher, cone crusher, ball mill and other equipment.

② Sorting

Magnetite is separated from gangue minerals by magnetic force and collected separately according to variety, which can be carried out by dry magnetic separator and wet magnetic separator.

③ Dehydration

The sorted magnetite is dehydrated to remove water and impurities.

④ Concentrate treatment

The dehydrated magnetite is processed to obtain the final concentrate product, which is carried out by equipment such as ball mill, thickener and roaster.

⑤ Tailings treatment

The tailings after sorting and dewatering are treated to reduce the impact on the environment through equipment such as tailings ponds and sedimentation tanks.

+8619138015336

+8619138015336