Introduction about Feldspar Beneficiation Process

Feldspar is an aluminosilicate mineral of alkali or alkaline earth metals such as potassium, sodium, calcium and barium, and is one of the important rock-forming minerals.

Due to the different mineral deposit types and ore properties, the mineral processing process of each feldspar is also different. Common feldspar beneficiation processes mainly include hand separation, desliming, magnetic separation, gravity separation, flotation and a combination of various beneficiation methods to remove quartz, iron, mica and other associated minerals.

Process of Feldspar Beneficiation Process

1. Preparation stage

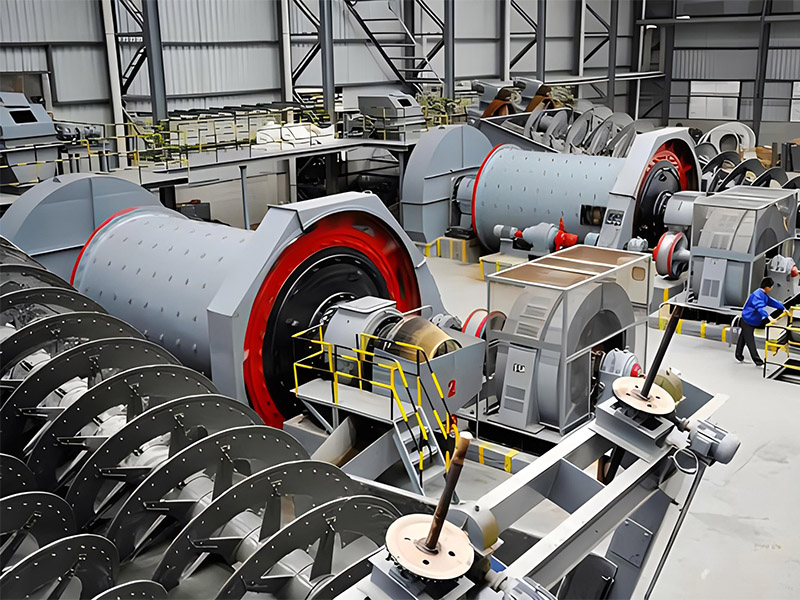

According to the process and feldspar property requirements, breaking can be divided into dry and wet grinding, dry grinding can be used Raymond grinding, stone grinding, wet grinding can be used stone grinding and ball mill.

2, Flotation stage

Hydrofluoric acid can be used as a medium regulator, and cationic amine collector is used to preferratively flotation feldspar to separate its quartz minerals. Sodium sulfonate can be used as a flotation agent to remove iron minerals and reduce the content of iron impurities in feldspar concentrate.

3, Magnetic separation stage

The magnetic separation equipment used includes drum magnetic separator, roll magnetic separator, magnetic bar, electromagnetic ring, etc., which has different advantages and disadvantages and feeding requirements in application, and needs to comprehensively consider the separation requirements, ore properties, economic benefits and other aspects to decide.

+8619138015336

+8619138015336